Things You Should Ask Before Using Molybdenum Disulfide

Here are a few essentials that you should know before you make a profitable switch from conventional lubricants to dry film lubricants:

When and why should I choose solid film coatings?

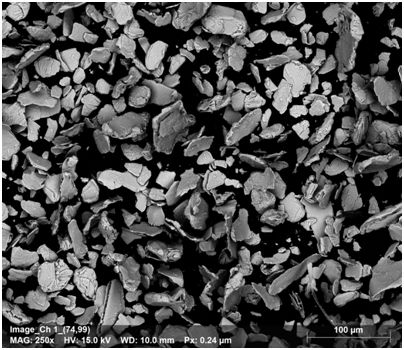

MoS2 Coating if you are looking for long term lubrication or better part performance and service life of lubricated components, you stand to benefit from the use of our molybdenum disulfide lubricants. We also recommend it for prevention of fretting and/or galling and corrosion protection.

What is the material compatibility of this lubricant?

This lubricant is best used with all types of ferrous and non-ferrous base materials. We also customarily supply products to be used on ceramics and plastics.

How do I select an appropriate coating for my application?

Micro Surface Corporation, Inc. experts are here to help. Our design and lubrications engineers are standing by to help you make the right choice by offering consultation and prototype service.

How long can I expect the Molybdenum Disulfide lubricant coatings to last?

The longevity of the lubricant coating primarily depends on factors such as the operating environment, load and pressure, temperatures, co-lubricants, and so on. However, our experience shows that these lubricants last up to 2-5 times longer than liquid or oil-based lubricants.

This article is about【http://en.shenyumoly.com Luoyang Shenyu Molybdenum Co., Ltd.】Originality, when reproducing, be sure to indicate the author and origin in the form of a link

ADD:http://en.shenyumoly.com/home-newsinfo-id-196.html

Address:Miaozi, Luanchuan, Luoyang, Henan PostCode:471000

Tel:+86 15503792966, +86 15565387688 Email:info@shenyumoly.com

Tel:86-379-69911868